Equipment for Bar Preparation for Thread Rolling

Equipment for Bar Preparation for Thread Rolling

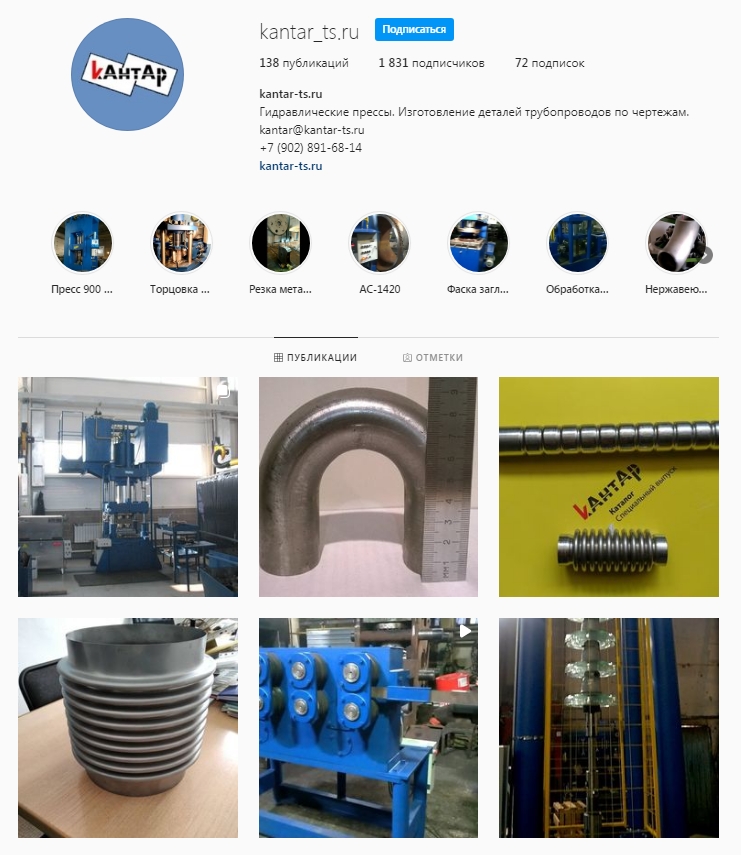

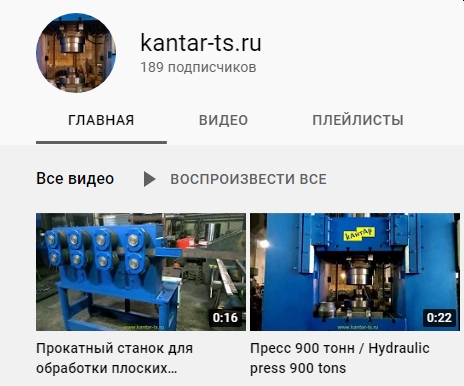

Our specialized equipment performs finishing treatment of metal bars prior to thread rolling. This two-stage process creates ideal conditions for forming high-quality, durable threads, ensuring superior results and process efficiency.

Equipment Lineup:

Chamfering Machine

-

Purpose: Precise chamfering on one or two sides of the bar.

-

Key Advantage: Prepares the edge and eliminates burrs, facilitating a clean start for the thread rolling process and preventing defects.

Cold Upsetting Machine

-

Purpose: Accurate diameter calibration combined with surface cold working (work-hardening).

-

Key Advantage: Strengthens the surface layer and enhances the metal's plastic properties. This fundamental improvement ensures easier, faster, and higher-quality thread rolling.

Final Result:

A perfectly prepared bar, ready for thread rolling, characterized by extended service life and consistently high performance, which reduces tooling wear and production costs.

.jpg)

.jpg)

Новости

- 26.12.2025 Merry Christmas and Happy Near Year!

- 08.04.2025 Equipment for stamping steel cups and sleeves

- 21.01.2025 Steel bar diameter reducing machine

- 28.12.2024 Bending copper tube

- 27.12.2024 Merry Christmas and Happy New Year!

- 27.12.2023 Merry Christmas and Happy New Year!

- 22.02.2023 Piping parts and equipment for the production of pipeline parts

- 28.12.2022 Happy New Year and Merry Christmas

- 04.02.2022 Mandrel For Elbow Forming

- 29.12.2021 Happy New year and Merry Christmas!

- News archive Newsletter